EPS provided a power management system to significantly reduce costs and improve profitablity

EPS has installed and created many power management systems during its history.

One of particular interest is a power management system that was designed for a food processing factory in Spain. This particular customer wanted a custom turbine operating regime to run at the ideal operating points to achieve the best financial results.

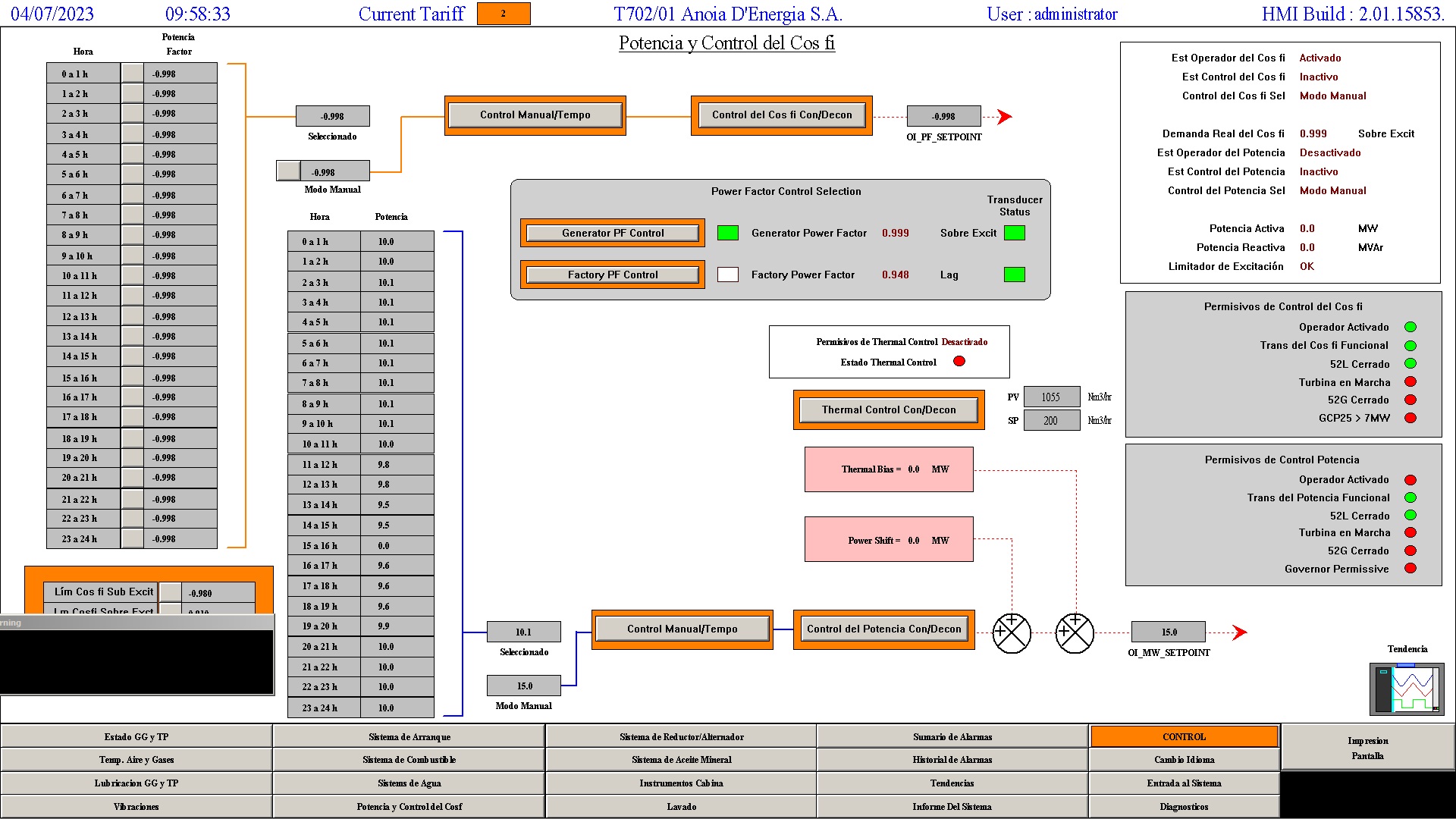

There are power and power factor manual and time-based control. The power factor control can be based upon the factory or the GT power factor.

EPS then created a Thermal Control mode. When selected, by monitoring the fuel consumption of the boiler, the control winds the GT power up or down to ensure that all of the energy in the exhaust gas is passed to the boiler. The boiler controller sets the position of the inlet damper, but by modulating the GT power we can ensure that the damper is always fully open to the boiler. This ensures the maximum overall efficiency of the complete system is considered.

A further control was created where an RSS feed for electrical export tariffs is brought in, as is the gas fuel cost, and a calculation can be undertaken to determine at what power the GT should be run to maximise the profit margin of the export power.

EPS also remapped the fuel system to allow the GT to be run with lower gas supply pressure. This allowed two large fuel gas compressors to be decommissioned with the associated running and maintenance savings. A number of control interlocks have been added to prevent undesirable running conditions from developing (such as running with the fuel metering valve being too far open).

EPS provides many upgrades for the driven equipment as well as software and system upgrades.

Gas Turbine Power Management Systems

Gas turbine power management systems are crucial components of modern power generation facilities, especially in applications where gas turbines are used to produce electricity. These systems are responsible for ensuring efficient and reliable operation of gas turbines while managing their performance, safety, and overall power output. Here’s an overview of how gas turbine power management systems work:

- Sensors and Data Acquisition: Gas turbine power management systems begin by collecting data from various sensors placed throughout the gas turbine and its associated systems. These sensors monitor parameters such as temperature, pressure, rotational speed, fuel flow rate, exhaust gas composition, and other relevant variables.

- Data Processing and Analysis: The collected data is processed and analysed in real-time. Modern gas turbine power management systems often utilise advanced algorithms and machine learning techniques to make sense of the data. The system compares the actual operating conditions with predefined performance parameters and operating limits.

- Control Algorithms: Based on the analysis, the power management system determines the optimal operating conditions for the gas turbine. It adjusts control parameters such as fuel flow rate, air intake, and power output to maintain efficiency and ensure safe operation. The system also anticipates load changes and adjusts the turbine’s output accordingly.

- Load Management: Gas turbine power management systems are responsible for load management, which involves optimising the turbine’s power output based on the current demand from the electrical grid. The system adjusts the power output to match the grid requirements while considering factors like efficiency, stability, and emissions.

- Safety and Protection: Ensuring the safety of the gas turbine and its associated systems is a critical aspect of power management. The system monitors parameters that could indicate potential malfunctions or unsafe conditions. If any parameter goes beyond safe limits, the system initiates protective actions such as reducing power output, shutting down the turbine, or activating safety mechanisms.

- Emissions Control: Gas turbines are subject to emissions regulations, and power management systems help ensure compliance with these regulations. By continuously monitoring exhaust gas composition and combustion efficiency, the system can adjust fuel-air ratios to minimise emissions of pollutants like nitrogen oxides (NOx) and particulate matter.

- Maintenance and Diagnostics: Gas turbine power management systems also play a role in maintenance planning and diagnostics. They can identify trends in data that might indicate wear and tear or potential issues. By predicting maintenance needs, the system helps operators schedule maintenance activities more effectively, minimising downtime and maximising the turbine’s availability.

- Human-Machine Interface: Operators and maintenance personnel interact with the power management system through a user interface. This interface provides real-time data, alerts, and controls, allowing operators to make informed decisions and take necessary actions.

In essence, gas turbine power management systems optimise the operation of gas turbines for efficiency, reliability, and environmental compliance. They rely on data-driven analysis and sophisticated control algorithms to ensure that the gas turbine operates within safe limits and delivers the desired power output while minimising emissions and maximising its lifespan.